Mitsubishi, Nippon Steel Secure LCO₂ Tank Steel Approval | Mariner News

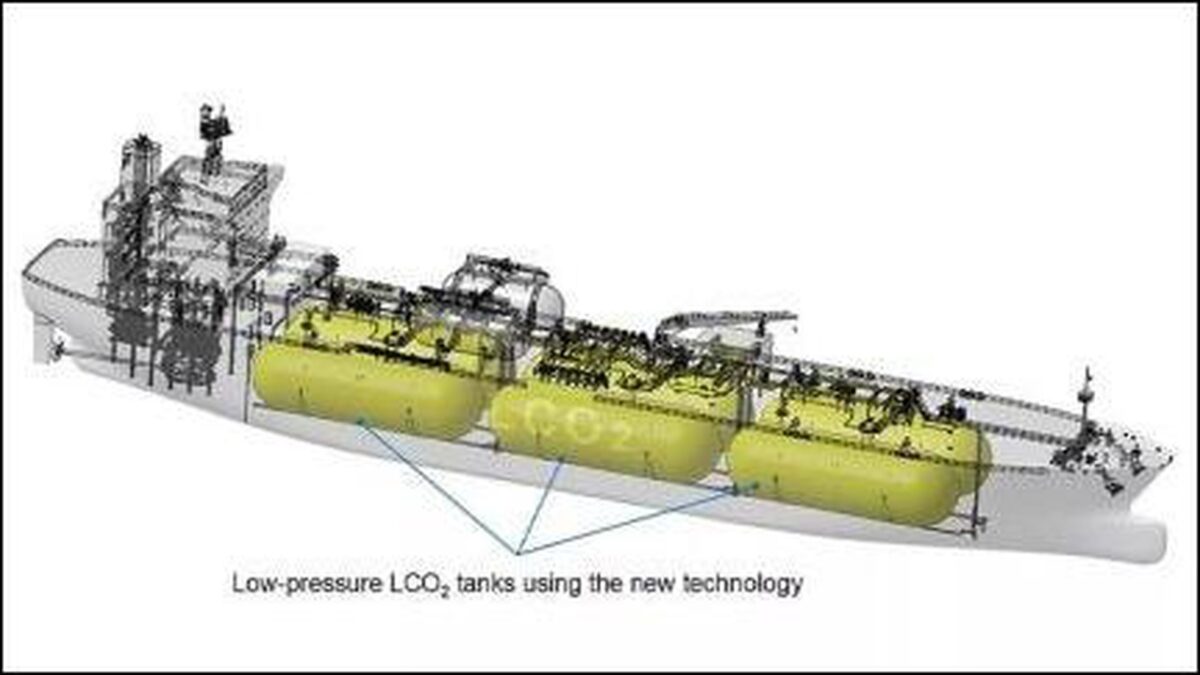

Mitsubishi Shipbuilding and Nippon Steel have achieved a significant milestone in marine innovation, securing the world’s first ClassNK General Design Approval (GDA) for new LCO₂ tank steel. This groundbreaking collaboration introduces high-strength carbon-manganese steel for the cargo tanks of liquefied CO₂ (LCO₂) carriers, a vital step towards enhancing safety and efficiency in the burgeoning carbon capture and storage sector.

Pioneering KF460 Steel Technology

The approved material, KF460 steel, developed by Nippon Steel, is specifically designed for large, low-pressure LCO₂ tanks. A key innovation lies in the exemption from post-weld heat treatment (PWHT), traditionally required under the International Gas Carrier (IGC) code. Mitsubishi Shipbuilding’s rigorous engineering critical assessment (ECA) confirmed the safety and validity of manufacturing these tanks without PWHT, overcoming a significant hurdle in large-scale tank production.

Boosting LCO₂ Carrier Efficiency

This exemption from PWHT dramatically streamlines the manufacturing process for LCO₂ carrier cargo tanks. It addresses the challenge of limited availability of suitable heat-treatment furnaces for large tank structures, accelerating the construction and deployment of new vessels. This advancement is crucial for the efficient transportation of captured carbon, supporting global decarbonization initiatives and sustainable shipping.

Advancing Marine Decarbonization

The joint effort by Mitsubishi and Nippon Steel sets a new standard for marine infrastructure, propelling the development of a robust LCO₂ value chain. This collaborative innovation underscores a strong commitment to environmental sustainability and technological leadership within the maritime industry, paving the way for a greener future for global shipping.