How Flyability’s Elios 3 UT Drone Sets New Standards for Ship Inspection Innovation and Safety

Flyability won the Innovation award in the Inspection Drones category for introducing a drone platform that streamlines and enhances inspection processes in challenging ship environments. It received the Safety award in the Remote Inspection Safety category for its significant contributions to reducing risks and improving worker protection during remote vessel inspections.

Innovation in ship inspections: Elios 3’s impact on maritime workflows

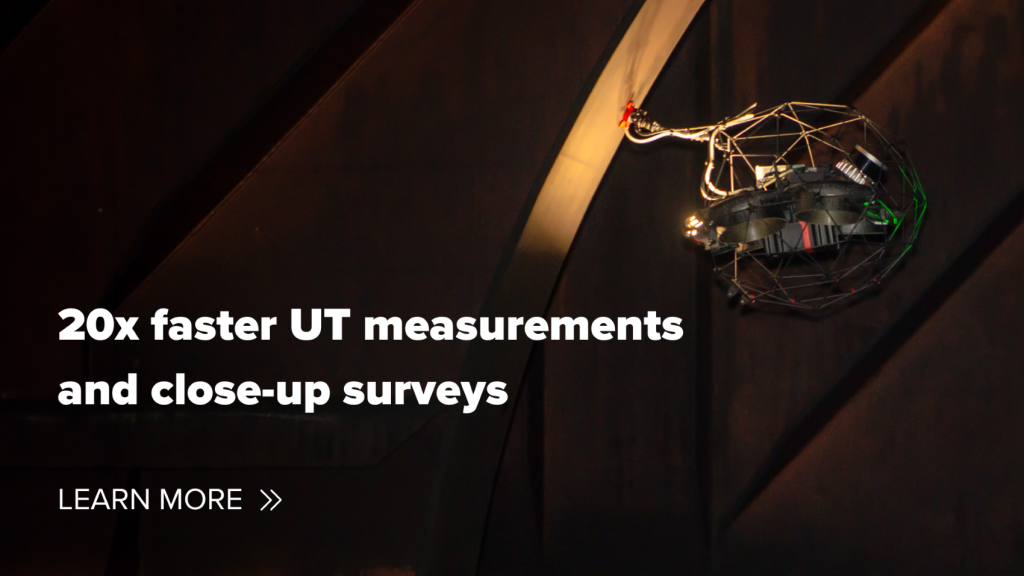

Flyability’s Elios 3 UT drone has introduced safer and more efficient capabilities for maritime inspections, particularly in challenging environments such as cargo oil tanks (COTs), ballast tanks, cargo hold, and ship hulls. These spaces are often characterized by limited access, complex geometries, and the absence of GPS signals, making them difficult to inspect using conventional drones or manual methods. Traditional inspection approaches typically require the construction of custom scaffolding, rope access, or even rafting, all of which have inherent risks, are resource-intensive and can extend inspection timelines from weeks to months.

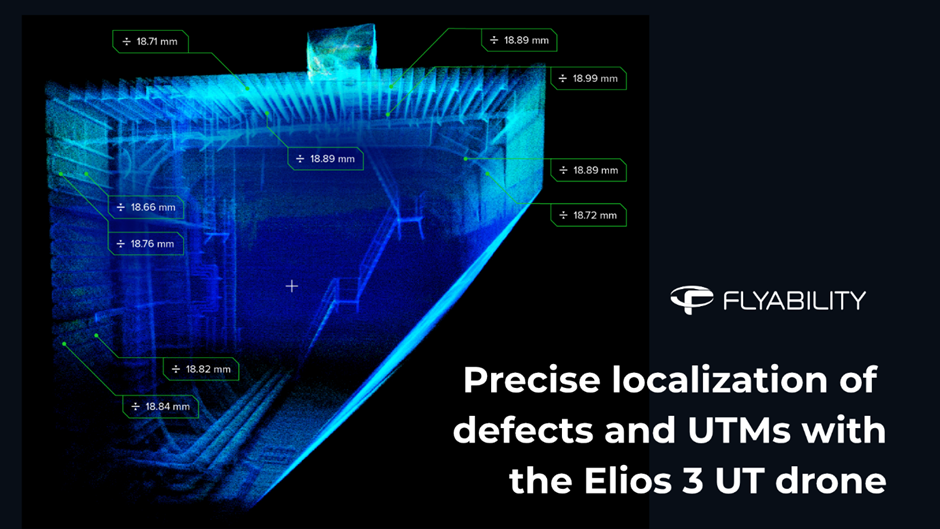

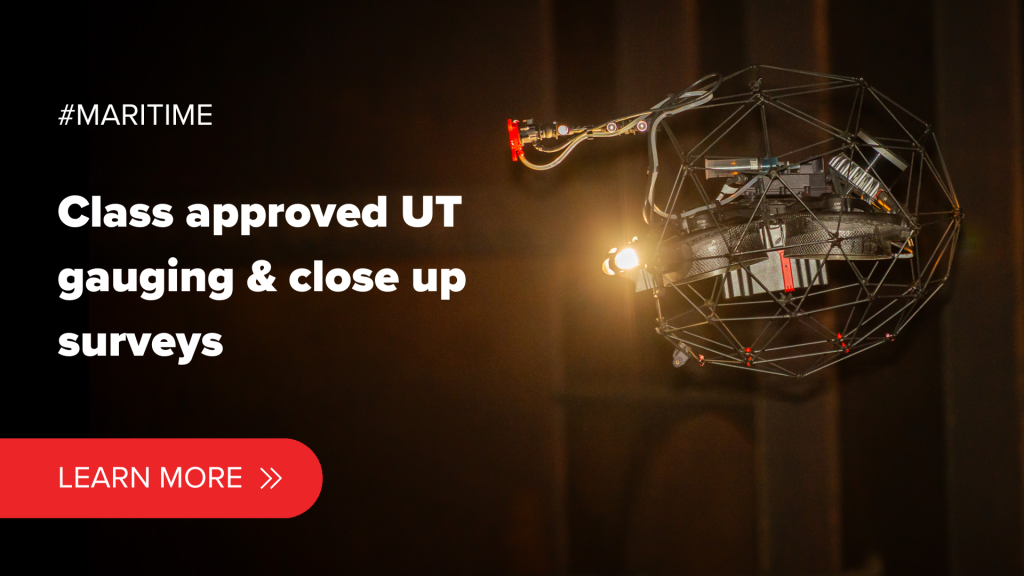

The Elios 3 addresses these challenges through a combination of advanced technologies and practical design. Its compact, collision-tolerant frame allows it to navigate through spaces as small as 50×50 centimeters (20 inches), enabling close-up inspections in areas that would otherwise be inaccessible. The integration of a LiDAR payload and an ultrasonic thickness (UT) measurement system—developed in partnership with Cygnus Instruments—enables the drone to simultaneously capture 4k videos, high-resolution 3D maps and precise UT readings during a single flight. This dual capability is particularly valuable for class-certified inspections, where both visual and thickness data are required. The strong reliability of the Cygnus Instruments solution, combined with the demonstrated consistency between Elios 3 UT measurements and handheld UT readings during field testing, further supports the acceptance of the data by class societies. The integration with the LiDAR data also enables a precise localization of defects and UT measurements within a digital twin of the vessel, allowing repeated inspection and streamlining the generation of reports.

The operational impact of these innovations is evident in real-world deployments. For instance, Cyberhawk, a global drone inspection provider, used the Elios 3 UT to complete 14 COT inspections in just seven days, averaging two tanks per day. Previously, each tank would have required at least a week to inspect using scaffolding or rope access. The Elios 3 UT’s ability to perform both visual and UTM inspections in a single operation further accelerates the workflow, reducing vessel downtime and associated costs.

Another example comes from TDBR Inspections, which utilized the Elios 2 and Elios 3 to inspect 63 ballast tanks on the 3R-2 offshore rig in Brazil over a 14-day period. The team completed 88 flights with just two staff members, a task that would have required a much larger team and significantly more time using traditional methods. The data collected was processed into 3D models, providing asset owners and class societies with detailed, actionable insights for maintenance and compliance.

The Elios 3 also streamlines reporting and data management. Its LiDAR system enables the creation of digital twins—accurate, navigable 3D models of ship structures—where every UT measurement and visual observation is precisely localized. This not only facilitates predictive maintenance and long-term asset management but also ensures that inspection data can be easily shared and reviewed by all stakeholders, including class societies such as ABS, ClassNK, and Bureau Veritas.

Furthermore, the Elios 3’s modular design and compliance with class society requirements mean that it can be used for official vessel certification and surveys. For instance, 3DTS, a Dutch non-destructive testing company, has obtained 7 class society certifications for using the Elios 3 UT drone for vessel inspection. The drone’s ability to consolidate multiple inspection steps into a single workflow, while maintaining high data quality and traceability, has led to significant cost savings. Case studies report savings of up to $1 million per vessel, driven by reduced labor, minimized downtime, and the elimination of costly scaffolding and equipment logistics. In a recent interview, Elios 3 UT user, DROBOTiQS, reported 1/3 cheaper and 5x faster class inspections compared to using traditional inspection methods.

Flyability’s collaborative approach—working with industry leaders and technology partners—has resulted in a solution that not only meets but often exceeds the evolving needs of the maritime sector. The Elios 3’s impact on inspection speed, data quality, and operational efficiency underpins its recognition for innovation in the industry.

Advancing remote inspection safety in the maritime sector

Safety remains a paramount concern in ship inspections, where traditional methods expose workers to a range of hazards, including confined space entry, work at height, and exposure to toxic atmospheres. The Elios 3 has been recognized for its significant contribution to remote inspection safety by fundamentally reducing or eliminating these risks, allowing the inspection to be completed from a safer location, like the deck.

One of the most notable safety benefits of the Elios 3 is its ability to perform inspections without requiring human entry into hazardous spaces. For example, during a hull survey conducted by C-Bird, the Elios 3 UT was used to inspect the interior of a cargo ship’s tanks, removing the need for scaffolding and preventing approximately 10,000 hours of high-risk labor. This not only protected inspectors from potential falls and manual handling injuries but also reduced the administrative burden associated with confined space entry permits and safety supervision.

The elimination of scaffolding, rope access, and rafting also minimizes the risk of foreign object damage—a common issue when equipment or tools are inadvertently left inside tanks. Such incidents can lead to costly unplanned outages if debris is drawn into cargo pumps or other critical systems. By keeping inspections remote and equipment minimal, the Elios 3 helps maintain vessel integrity and operational continuity.

The safety improvements extend to the broader crew and operational environment. On offshore rigs like the 3R-2, where the number of personnel on board (PoB) is tightly controlled, the ability to conduct inspections with a small team from a safe location optimizes crew allocation and reduces overall exposure to hazardous conditions. This approach also streamlines logistics, as fewer people and less equipment need to be transported to and from the vessel.

An additional layer of safety comes from the Elios 3 integrated LEL gas sensor that allows pilots to detect over 11 types of flammable gas concentrations in real time. This sensor helps reduce the operational risks posed by gases in cargo holds or ballast tanks.

Environmental safety is another area where the Elios 3 delivers measurable benefits. Traditional rafting methods for tank inspections generate large volumes of oil-contaminated water, which must be treated before disposal. By enabling remote, drone-based inspections, the Elios 3 eliminates the need for such environmentally impactful procedures.

The Elios 3’s data quality and reliability are critical for regulatory compliance. The drone’s inspections have been accepted by major class societies, ensuring that asset owners can meet inspection requirements without compromising safety. The ability to provide class-approved, high-quality data from a safe distance is a key factor in the Elios 3’s recognition for advancing remote inspection safety.

Case studies from Cyberhawk, Interocean, C-Bird, 3DTS, DROBOTiQS, and TDBR Inspections consistently highlight the reduction in high-risk labor hours, the elimination of hazardous work practices, and the improved safety outcomes achieved through the use of the Elios 3. These results demonstrate the drone’s effectiveness in addressing long-standing safety challenges in the maritime industry.

“We are honored at Flyability to receive these awards, which recognize our commitment to making vessel operations and inspections both safer and more efficient. The Elios 3 UT drone reflects years of innovation driven by our mission to protect workers by reducing confined space entry and work at height. The Elios 3 UT is not just a product—it’s a step toward a safer, smarter future in the shipping industry, and at Flyability, safety and innovation will always be at the heart of what we do.”

– Patrick Thévoz, CEO & Co-founder, Flyability

Company Profile

Flyability is a global leader in confined space inspection technology, serving critical sectors including maritime, oil and gas, power generation, and others. With a presence in over 60 countries, Flyability’s indoor drone solutions are used by shipping, offshore, and oil &gas companies worldwide to enhance safety and operational efficiency.

Pioneers in collision-tolerant drone technology, Flyability developed the Elios drone series—the world’s first drones designed for GPS-denied, confined, and hazardous environments. The Elios 3, integrated with advanced payloads such as LiDAR, gas sensors, and ultrasonic testing (UT), allows inspectors to collect high-quality data inside ballast tanks, cargo tanks, storage tanks, and more without risking human lives and saving hundreds of thousands in the process.

According to Chris Leontopoulos, EMEA Vice President, Technology at ABS, “This technology offers a safer alternative, reducing the need for workers to climb and access dangerous locations. As a result, inspections and measurements can be completed more quickly and efficiently.”

Driven by the mission to make hazardous inspections safer, faster, and more cost-effective, Flyability continues to push the boundaries of robotics and data capture technology. Since its founding in 2014, the company has remained at the forefront of industrial innovation and is trusted by global leaders across the world.”

Contact Details

Matteo Saglia, matteo.saglia@flyability.com

Links:

Website: https://mkt.flyability.com/maritime-drones