There’s an obvious fuel saving advantage, but partnering energy storage systems with new fuels brings other advantages too.

There’s a new generation of vessels emerging which is exemplified by Grimaldi’s PCTC Grande Shanghai, claimed to reduce fuel consumption by 50% compared to previous-generation car carriers, and the NCL Vestland, a container feeder vessel similarly claimed to reduce energy consumption per TEU per nautical mile by 63%.

What these vessels have in common is a propulsion system that combines energy storage systems and new fuels.

As Henrik Helgesen, Senior Environmental Consultant at DNV, points out, the price of maritime batteries is dropping, and including them allows power systems using new fuel engines to respond to load changes better. Batteries help the engines to run more efficiently, reducing the cost of burning new fuels such as methanol and ammonia.

It’s a benefit that is not restricted to cargo vessels.

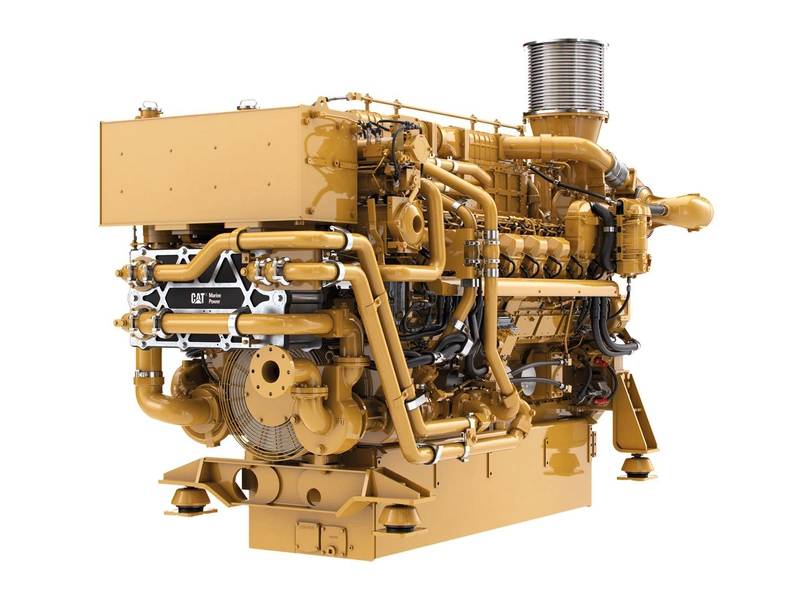

In March, SAAM Towage and Caterpillar Marine signed a MoU to implement alternative power solutions including electrification and alternative fuels in the tug fleet.

Caterpillar Marine aims to have a marine lithium iron phosphate battery on the water by early 2026 which will be liquid cooled, have a 1C discharge rate and a voltage of up to 1420VDC. Additionally, a hybrid propulsion system is currently in development that will consist of a propulsion engine, clutch, electric motor, variable frequency drive, battery system, auxiliary genset and controls.

The NCL Vestland is one of two identical sister ships built to DNV class and delivered this year by Taizhou Sanfu Ship Engineering. The 1300-TEU methanol dual-fuel container feeder is part of an initiative by Norwegian owner, MPC Container Ships, and the long-term charterer, North Sea Container Line (NCL), to establish a green corridor for container shipping between Norway and the Dutch and German North Sea ports.

The NCL Vestland is one of two identical sister ships built to DNV class and delivered this year by Taizhou Sanfu Ship Engineering. The 1300-TEU methanol dual-fuel container feeder is part of an initiative by Norwegian owner, MPC Container Ships, and the long-term charterer, North Sea Container Line (NCL), to establish a green corridor for container shipping between Norway and the Dutch and German North Sea ports.

Image courtesy NCL“What we’ve learned in collaborating with vessel operators, naval architects, and shipbuilders is that there truly is not a single solution that fits all applications. What is appropriate for a passenger vessel won’t meet the needs of a tug, for example. Flexibility is key,” says Watson.“This is why we’re focused on fuel flexibility and multiple power options that can be customized for a vessel’s unique needs. Holistic marine power solutions that allow optimal transit speeds, improved fuel efficiency, and lower operating costs are a top priority. Lower-carbon intensity fuels are crucial for this reason and complement battery power to create reliable hybrid solutions that reduce diesel fuel consumption.”

Oskar Levander, VP Strategy and Business Development, Kongsberg Maritime, says: “The market trends we’re seeing toward larger energy storage systems and alternative fuels aren’t theoretical — they’re already appearing in advanced vessel projects.” A standout example is Kongsberg Maritime’s new UT7623 SEV (Sustainable Energy Vessel) design for Olympic. The vessel owner has ordered two multipurpose subsea vessels which combine methanol-ready dual-fuel engines with a hybrid battery system.

The UT7623 SEV can operate in battery-only mode for zero-emissions in port, use the batteries as spinning reserve to allow fewer engines online at optimal load, and smooth load fluctuations to enhance engine performance and extend maintenance intervals. For offshore operations, the energy storage system can deliver extra power for high-demand moments — such as ROV deployment or maneuvering in heavy seas — without oversizing the main engines.

Levander says Olympic’s choice of a fully integrated package from Kongsberg Maritime — including rim-drive propulsion, retractable azimuth bow thrusters, hybrid-ready power distribution, and advanced automation — demonstrates that the most efficient solution comes from treating energy storage and new fuels as part of a single, unified system architecture.

Energy storage systems enable the installation of larger power take off (PTO) systems. The size of a PTO is usually limited to a certain maximum percentage of the engine power to ensure the engine can cope in all situations, but with a battery system, a larger PTO can be installed while still enabling smooth operation of the engine by taking up sudden load peaks and fluctuations.

Under FuelEU Maritime rules, battery operation with shore power counts as zero emissions, generating a compliance surplus that can be pooled or sold. For vessels like the UT7623 SEV, this means the batteries are not only an environmental asset but also a financial one, offsetting the higher cost of alternative fuels.

Caterpillar Marine is focused on fuel flexibility and multiple power options that can be customized for a vessel’s unique needs.

Caterpillar Marine is focused on fuel flexibility and multiple power options that can be customized for a vessel’s unique needs.

Image courtesy Caterpillar

The Olympic case reinforces the importance of planning for charging infrastructure. While these vessels are designed to be methanol-ready and globally capable, their full low-carbon potential will depend on the availability of shore power in the ports they serve — a challenge the entire industry must address, says Levander.Electrical installations are becoming increasingly complex as new types of power sources and loads are added to systems, in contrast to traditional installations where the load and machinery configuration are well understood, says Jin Wang, Director – Energy Transition, Technology Americas, ABS. New power system architecture, such as medium-voltage direct current (MVDC), also requires new understanding of protection and safety management by designers and operators.

In August, ABS issued a new technology qualification certificate to HD Korea Shipbuilding & Offshore Engineering and HD Hyundai Heavy Industries for their MVDC power system for ships. MVDC technology is generally operated at 8kV DC to 11KV DC and is particularly suitable for large vessels that require tens of megawatts of power.

“The MVDC power systems provide a promising solution for performance improvement in hybrid and all electric power systems, especially for large vessels,” says Wang. The absence of frequency constraints in DC systems allows for smaller and lighter generators, transformers, and switchgear, contributing to overall ship weight reduction. Energy efficiency is improved by reducing power losses from generation to propulsion, and it enables seamless integration of diverse power sources such as diesel engines, fuel cells, renewable power sources, and li-ion batteries.

New designs continue to emerge, and the trend for electrification, batteries, and new fuels is extending beyond smaller and short-sea vessels. As well as providing classification for the Grande Shanghai, RINA recently granted approval in principle for a wind-assisted, battery-assisted, dual fuel LNG/hydrogen-powered ultramax bulker design developed by Almi Marine Management and SDARI.

The new concept redefines propulsion in merchant shipping, says RINA.

Kongsberg Maritime’s new UT7623 SEV (Sustainable Energy Vessel) design for Olympic.

Kongsberg Maritime’s new UT7623 SEV (Sustainable Energy Vessel) design for Olympic.

Image courtesy Kongsberg Maritime