Mia Elg, R&D Manager at Deltamarin, says there’s not many of the company’s new designs, no matter what the vessel type is, that don’t include batteries.

Installing smaller battery capacity to a diesel engine driven vessel with electrical power train can enable spinning reserve. Here, an optimal number of engines can be kept online, and the batteries can work as a black out preventer. This can save, depending on the type of the ship and operation, anything between a few percent to tens of percent if the ship is otherwise required to keep a huge reserve of engines online.

In addition to spinning reserve, the batteries can perform peak shaving function, to further ensure that the engines are kept on fixed load close to the fuel efficiency optimum point. For these two functions, the battery capacity does not have to be large. It is mainly for various zero emission operation modes or even covering the main voyage time, when larger capacities are required.

Having batteries for spinning reserve or peak shaving for a cargo’s ship auxiliary machinery powertrain can also similarly optimize the genset efficiency. Cargo ships typically have large thrusters or cranes that take large quantities of power for a short time. In this case, battery capacity may replace the need of one auxiliary genset.

The fuel savings in battery-hybrid or battery driven ships are strongly related to the fuel, machinery configuration, and operational profile of the ship, says Elg. “We have recently studied, for instance, for an LNG-fueled RoPAX ship type with two kinds of battery sets for various routes: a smaller but still multi-MWh sized battery pack, mainly used for spinning reserve and peak shaving, and a fully electric RoPAX.

“In the smaller battery pack case, the savings are very much depending on the route. We looked at a route in the Mediterranean with rather long distance and fixed speed at sea with very little maneuvering, the route across English Channel and a route at Baltic Sea, including much maneuvering in the archipelago at variating speed.

“Since the selected base line machinery was very efficient, the fuel savings were moderate, from 0.5% to less than 5% in all cases. But with different fuels and, for instance, older machineries the savings may be larger. Therefore, battery retrofits with smaller capacities are also interesting at the moment for many ship owners.”

Deltamarin also analyzed the potential of batteries for a fully battery powered RoPAX operating on the English Channel route. “The design would be more feasible to achieve, and I believe it is not so much fuel saving we should focus on but the operational total costs.”

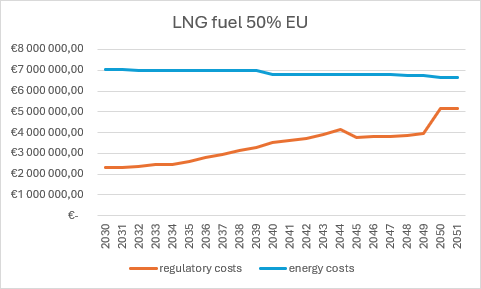

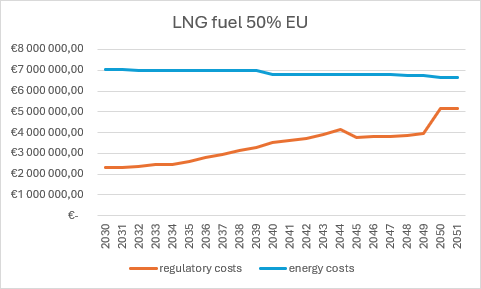

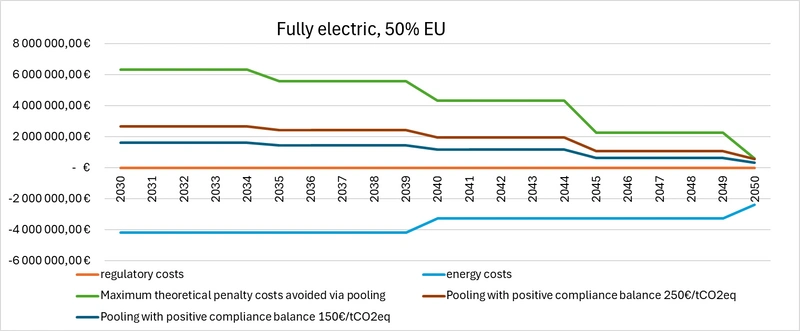

Depending on actual electricity prices over the next few decades, the overall pure energy costs for the vessel would be less than for LNG.

Additionally, depending on the price put on carbon, it might be possible to pool the vessel and get some additional income. This could reach several million euros per year and would cover much of the installation costs for the batter system.

“This is to me a key feature why in some cases batteries make more sense before alternative fuels at least here in Europe,” says Elg.

Should the batteries be combined to alternative fuels or renewables?

“We must always understand the vessel big picture for answering this. In general, you could say that having energy saving and renewable power like wind or sun, reducing the power usage onboard is always positive. Batteries could also even out the peaks due to renewables not being there all the time.”

Ships with fuel cells and hydrogen as fuel, for instance, will likely need batteries, but when comes to other fuels, it is good to find a balance between CAPEX and the number of technologies used onboard. “For instance, for an ocean-going cargo vessel, batteries will not anyway be a solution to power them 100%. In those cases, it could be sensible to prepare the main propulsion machinery for alternative fuels such as methanol or ammonia, and batteries could be utilized to boost the auxiliary power train.”

It is standard today to include a PTO/PTI configuration on many cargo vessels, says Elg. This means that at sea, typically, the auxiliary engines are not used in normal operation. Depending on the installed battery capacity, they could do more than just serve as spinning reserve. Combined with shore power, they could be used for zero emission harbor arrival and departure.

“If it is possible to connect the batteries to shore side charging, electricity could be seen as one of the alternative fuels,” she says.

However, introducing new equipment inevitably introduces added weight to the ship and added investment. Ship electrification might also not be possible in all locations without considerable investment in infrastructure, so all projects are very case-dependent.

“I have noticed that today there exists companies that have as business to provide energy storage solutions including the batteries and charging infrastructure, also for harbors. Therefore, the ship owner or port operator actually does not have to necessarily invest much CAPEX in the electrical infrastructure, but they may pay a monthly fee or premium on top of the electricity price for the service. It just makes this electrification even more interesting and feasible to ship operators.”

In some cases, it might be sensible to prepare the ship for a variety of energy-saving technologies or electricity storage, but to install some of the capacity later when the economical calculations support it.

“It is a balancing exercise, and this is why we have introduced digital design and energy system modelling processes in our designs, both for newbuilding and retrofit projects.”